"The Lurktastic Opponaught" (oppolurker)

"The Lurktastic Opponaught" (oppolurker)

08/25/2016 at 21:05 • Filed to: 1972 KE175

3

3

6

6

"The Lurktastic Opponaught" (oppolurker)

"The Lurktastic Opponaught" (oppolurker)

08/25/2016 at 21:05 • Filed to: 1972 KE175 |  3 3

|  6 6 |

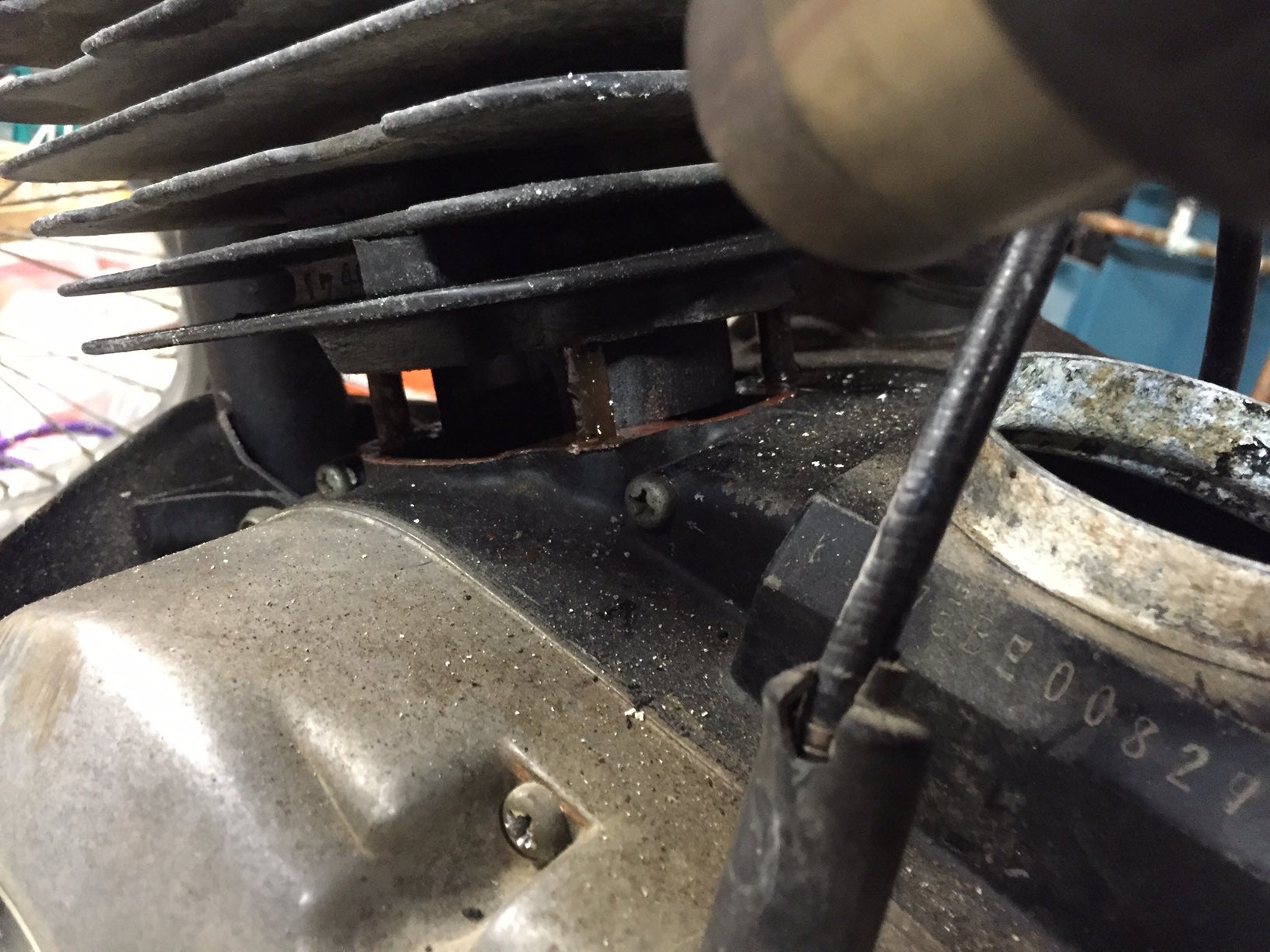

I gave it about 15 minutes with a combination of crushed dry ice in the bore and heat from a milsuckee heat gun on the cooling fins before attempting some percussive maintenance.

After thoroughly heating the circumference of the cylinder and about 3 full-wind-up smacks with a rubber mallet, this happened:

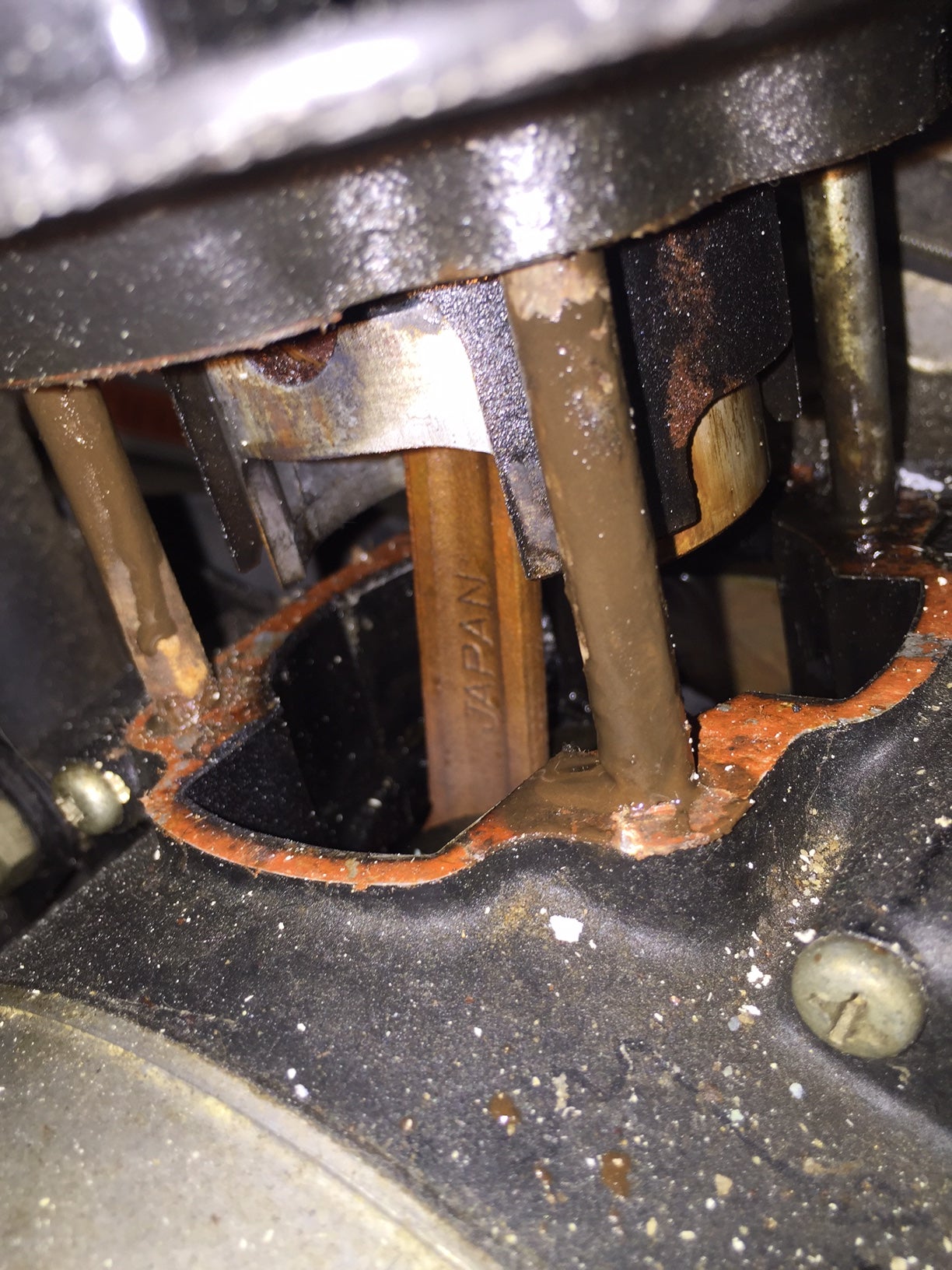

Color me surprised- Clarkson was right. So I packed it with more dry ice and kept at it with the heat gun and a slower, more tender approach with the mallet, and about 10 minutes later I’d managed to accomplish this:

At this point the last remaining dry ice fell out the exhaust port, and I decided that this was enough physical labor for one night. I deemed it time to liberally apply head-altering chemicals. Namely, more PB Blaster. Now we wait until I get another package on dry ice and we see if I can finish the job.

With all that rust and mud (?!) around the studs, connecting rod and wrist pin, how hosed am I? What’s the over/under on this pig ever running again? Do I keep on with the dream? Or do I buy a cheap harbor fright welder, a lawnmower engine, and a fleabay CVT and go out in a flaming ball of road-legal glory?

Stephenson Valve Gear

> The Lurktastic Opponaught

Stephenson Valve Gear

> The Lurktastic Opponaught

08/25/2016 at 21:39 |

|

Good start. It will run... just depends on what else you find wrong, and how much you are willing to fix. My dad collects antique hit & miss engines - I can remember him bringing home a relic that had been sitting outside for decades, packing the cylinder full of grease, then making an adapter for a zerk fitting for the spark plug hole. Connect up a grease gun, and s-l-o-w-l-y push the piston out of the bore. I believe he would generally do that to get the piston moving, then switch over to an oak board & big hammer to finish the job. More than one way to skin a cat... but in the end, it is all the same to the cat!

The Lurktastic Opponaught

> Stephenson Valve Gear

The Lurktastic Opponaught

> Stephenson Valve Gear

08/25/2016 at 21:45 |

|

Good idea, thanks. I’m under the general impression that these old two strokes are hard to kill, and the price was certainly right. I’m about six dollars into the project for the can of PB, so not too bad. It’s going to need a new rear tire, a new right hand side of the handlebars assembly, and a right rear turn signal to complete repairs from a crash the previous owner managed, but it was all for naught if I couldn’t get the piston unstuck. If I can’t manage to finish the job with heat/cold, I’ll give your hydraulic idea a try. It’s a neat idea.

Stephenson Valve Gear

> The Lurktastic Opponaught

Stephenson Valve Gear

> The Lurktastic Opponaught

08/25/2016 at 21:53 |

|

Well, except that on your two-cycle you already have the ports uncovered, so the grease gun isn’t an option... heat + hammer is about the only workable technique from here on out. But, the piston has moved, and I would bet money that you will get it out intact. If the bearings are in good condition and the crank seals are intact, you will have the hardest part done!

The Lurktastic Opponaught

> Stephenson Valve Gear

The Lurktastic Opponaught

> Stephenson Valve Gear

08/25/2016 at 21:59 |

|

Yeah, I thought of that after I posted. I should have mentioned the difficulty level going on here: complete noob.

Stephenson Valve Gear

> The Lurktastic Opponaught

Stephenson Valve Gear

> The Lurktastic Opponaught

08/25/2016 at 22:06 |

|

Hey, you are doing good. This is the best way to learn!

The Lurktastic Opponaught

> Stephenson Valve Gear

The Lurktastic Opponaught

> Stephenson Valve Gear

08/25/2016 at 22:57 |

|

Thanks! Any chance you could recommend a decent new or used parts supplier? Now that I can see past the unsticking, I’m going to need parts.